Coordinate measuring machines: bridge type CMMs, horizontal arm CMMs

select brand

3D measuring machine - 200 x 200mm - 300 x 300mm | PMS-Series

The PMS series is a line of 3D multisensors manufactured by Dr. Schneider. It features a measurement data acquisition and management including program management in compliance to FDA 21 CFR part 11.

The unit performs...

The unit performs...

3D measuring machine - 200 x 200mm - 300 x 300mm | PMS-Series

The PMS series is a line of 3D multisensors manufactured by Dr. Schneider. It features a measurement data acquisition and management including program management in compliance to FDA 21 CFR part 11.

The unit performs control, measurement, and analysis within one software. It is equipped with dust-proof precision guides, and a mechanical-resistant cabling system. The device showcases a robust granite table with high stiffness. It ensures high precision measurement and speed.

The PMS can be supplied with a touch-trigger probe TP200, or scanning probe SP25. It has an optional conoscopic measuring laser, and a switchable sectored incident illumination. The multisensor can be retrofitted with additional sensors any time. It has temperature stability due to its solid construction, and the optional temperature compensation function of the tool and machine.

The unit performs control, measurement, and analysis within one software. It is equipped with dust-proof precision guides, and a mechanical-resistant cabling system. The device showcases a robust granite table with high stiffness. It ensures high precision measurement and speed.

The PMS can be supplied with a touch-trigger probe TP200, or scanning probe SP25. It has an optional conoscopic measuring laser, and a switchable sectored incident illumination. The multisensor can be retrofitted with additional sensors any time. It has temperature stability due to its solid construction, and the optional temperature compensation function of the tool and machine.

Crankshaft coordinate measuring machine (CMM) - PMS 600 CS

The PMS 600 CS is a 3D multisensor measuring unit that is made to measure crankshaft. It has a...

Crankshaft coordinate measuring machine (CMM) - PMS 600 CS

The PMS 600 CS is a 3D multisensor measuring unit that is made to measure crankshaft. It has a hard and accurate granite construction with holding device for camera. It features a rotary spindle support 125, and is motorized with a rotary for the horizontal holding of crankshaft.

The measuring range of the product is 600 x 600 mm. The surface area is 800 x 770 mm.

The measuring range of the product is 600 x 600 mm. The surface area is 800 x 770 mm.

3D measuring machine - PMS LL

The 3D multi-sensor portal measuring machine PMS LL has three sensors. Their measuring range is 600x600x600mm to 1200x1200x600mm. There is an air-bearing guideway in all axes. The measuring...

3D measuring machine - PMS LL

The 3D multi-sensor portal measuring machine PMS LL has three sensors. Their measuring range is 600x600x600mm to 1200x1200x600mm. There is an air-bearing guideway in all axes. The measuring...

Coordinate measuring machine (CMM) with multiple sensors - PMS 600 T

The PMS 600 T is a 3D multisensor machine. It is well suited for measuring of tools. An extensive object...

Coordinate measuring machine (CMM) with multiple sensors - PMS 600 T

The PMS 600 T is a 3D multisensor machine. It is well suited for measuring of tools. An extensive object...

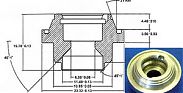

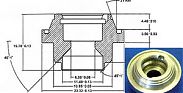

3D measuring system / parts

This is a 3D part measuring system manufactured by SMAC Moving Coil Actuators. It comes with its mini inline XYZ gauging structure that supplies a capability of...

3D measuring system / parts

This is a 3D part measuring system manufactured by SMAC Moving Coil Actuators. It comes with its mini inline XYZ gauging structure that supplies a capability of 100% parts inspection. A correction assessment through its instant feedback and adaptation in its manufacturing process is also included. It is also built with an ability to provide a volume of up to 100 cubic mm that can be covered a sole system. The actuator systems are capable of quantifying various mechanism. This incorporates both internal and external dimensions, bores, threads, grooves and others. The SMAC measurements can easily be corresponded to manual gauge methods.

2D part inspection unit

The SMAC unique electric actuator configuration, such as is used in SMAC XY/XYZ systems, provide users with 100% parts inspection capability. SMAC offers complete inline shop floor quality measurement verification. The actuator systems are able to measure...

2D part inspection unit

The SMAC unique electric actuator configuration, such as is used in SMAC XY/XYZ systems, provide users with 100% parts inspection capability. SMAC offers complete inline shop floor quality measurement verification. The actuator systems are able to measure numerous features, unlike lasers and cameras. While checking for burrs, they can simultaneously check for threads, bores, grooves, and internal and external dimensions. All of this is carried out on machines in a shop floor environment.

Originally carried out by human hand, this fully automated solution is now utilized to 100% measure and test the inline production of automotive parts. These include air bag components and molded parts requiring a total dimension check. The Moving Coil Actuator from SMAC includes the unique 'Softland' function which allows the user to program the speed and positional feedback completely as per requirement. This means that surfaces or positions in spaces can be found without damaging the component or SMAC actuator.

Originally carried out by human hand, this fully automated solution is now utilized to 100% measure and test the inline production of automotive parts. These include air bag components and molded parts requiring a total dimension check. The Moving Coil Actuator from SMAC includes the unique 'Softland' function which allows the user to program the speed and positional feedback completely as per requirement. This means that surfaces or positions in spaces can be found without damaging the component or SMAC actuator.

Length measuring system / profile / for tubes / automatic - max. 3 000 p/h, ø 101.6 mm | RASACHECK A

The RASACHECK A is an integrated device ingested into the sawing centre that serves as a universal length measurement module for different shapes like round, square and rectangular tube....

Length measuring system / profile / for tubes / automatic - max. 3 000 p/h, ø 101.6 mm | RASACHECK A

The RASACHECK A is an integrated device ingested into the sawing centre that serves as a universal length measurement module for different shapes like round, square and rectangular tube. The machine automatically ejects all reject parts quickly.The mechanical measurement system tests every work piece with the use of two measuring plates. The rejected parts are detected and they will be automatically ejected from the process. Then, they will be put together in a separate container that keeps the batch from contamination considering the tolerance parts. The unit serve to be an interface for electronic capture and analysis of measurement data. On request, fully automatic check of the tube-end geometry can be incorporated.

Length measuring system / profile / for tubes / automatic - max. 5 000 p/h, ø 60 mm | RASACHECK AT

The RASACHECK AT is an automatic length-measuring system for tubes and profiles, manufactured by RSA cutting systems GmbH. This product is commonly used for round tubes that is integrated...

Length measuring system / profile / for tubes / automatic - max. 5 000 p/h, ø 60 mm | RASACHECK AT

The RASACHECK AT is an automatic length-measuring system for tubes and profiles, manufactured by RSA cutting systems GmbH. This product is commonly used for round tubes that is integrated in the sawing center and automatically ejects each reject parts. It is defined by a high precision system via the interplay of laser measurement and function piece transport.

The transports is operated by the use of continued discs that are free of play, which its part measurement is free from contact. Tubes outside the tolerance are ejected automatically and collected in independent container. With this, the batch is kept from being contaminated. The whole line is off if a maximum value of denied parts is reached.

The transports is operated by the use of continued discs that are free of play, which its part measurement is free from contact. Tubes outside the tolerance are ejected automatically and collected in independent container. With this, the batch is kept from being contaminated. The whole line is off if a maximum value of denied parts is reached.

Length measuring system / profile / for tubes / automatic - ø 6 - 101.6 mm | RASACHECK M

The RASACHECK M is suitable for the handheld random samples that are up to 4,500 mm long. It is characterized...

Length measuring system / profile / for tubes / automatic - ø 6 - 101.6 mm | RASACHECK M

The RASACHECK M is suitable for the handheld random samples that are up to 4,500 mm long. It is characterized by its simple operation.

The work piece is located between the two measurement plates; one of them can be manually moved. The digital display clearly shows the results of the measurement. The data can be transferred to the QS-software.

There is no set up needed to change the diameters.

The work piece is located between the two measurement plates; one of them can be manually moved. The digital display clearly shows the results of the measurement. The data can be transferred to the QS-software.

There is no set up needed to change the diameters.