Chain transmission

In order to handle higher power transmission requirements such as for vehicle transmission systems for example, transmission chains in the form of inverted tooth chains (also known as silent chains) are used. In addition to providing kinematically optimized meshing of the toothed links with the sprocket teeth, the principle of randomizing is also applied, i.e. fitting tooth link plates which have a different contour from the standard plates. Staggering standard and non-standard link plates breaks the monotony of the contact pulses and consequently the chain noise is rendered unobtrusive.

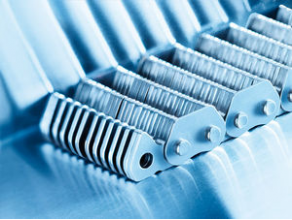

In order to handle higher power transmission requirements such as for vehicle transmission systems for example, transmission chains in the form of inverted tooth chains (also known as silent chains) are used. In addition to providing kinematically optimized meshing of the toothed links with the sprocket teeth, the principle of randomizing is also applied, i.e. fitting tooth link plates which have a different contour from the standard plates. Staggering standard and non-standard link plates breaks the monotony of the contact pulses and consequently the chain noise is rendered unobtrusive.Inverted tooth chain with single pin joints

Inverted tooth chains with single pin joints can be used for applications with very high power transmission requirements. The compact design and simplicity of this type of joint permit the manufacture of highly efficient, inexpensive and performance-optimized chains.

Inverted tooth chain with rocker pin joints

To reduce friction losses even further, inverted tooth chain with rocker pin joints are used. A rocker pin joint comprises two rocker pins, with one pin being fixed in the tooth link plates of the inner link and one being fixed in the tooth link plates of the outer link. The two pins then roll against each other as the chain enters and exits the sprocket.