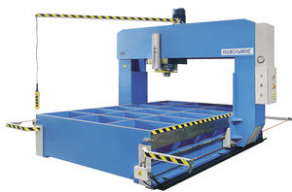

Straightening press / hydraulic - 300 t / TL-300

We have designed the T-series hydraulic presses with 3 different power ranges, from 150 to 300 tn

We have designed the T-series hydraulic presses with 3 different power ranges, from 150 to 300 tnThey are especially designed for the straightening of electro welded structures and flame cut sheets

Their design facilitates the loading and unloading of large volume structures. It allows the different pressing points to be accessed without the need to move the part thanks to the lateral displacement of the cylinder and the longitudinal displacement of the bridge

Consist of an electro welded structure made solely of ST-52.3 steel. They are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision. Calculated and designed by finite software with level 5 structural resistance

The longitudinal displacement of the bridge is carried by frequency inverter and cogged belt to ensure precise and sensitive slides. The lateral movement of the head is motorized

The cylinder is double acting with a lapping liner, chrome plunger and maintenance-free anti wear guides, its fitted with a removable and interchangeable hold-down plate. Includes an anti-turning of the cylinder and a squared front with stroke endings

The motorised 2 speed hydraulic unit has automatic rapid speed disconnection. It includes a cylinder decompression valve and a pressure regulator

The control panel features a switch enabling the user to select the desired type of work in a manual or semi-automatic position and a switch to select either the fast speed or slow speed

Operation is carried out by means of a pendant control station with an emergency stop and low-voltage operation

Safety is guaranteed by a line-operated safety installed on the perimeter