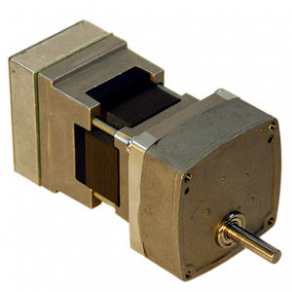

Brushless electric gearmotor / DC / spur - 12 - 48 VDC, max. 149 in-lb | NT DYNAMO®

Some factors to consider in maximizing your application systems performance:

Some factors to consider in maximizing your application systems performance:Torque Multiplication

Radial Loading

Noise

Speed Reduction

Axial Loading

Inertia Matching

Spur gearheads will suit most needs in relatively low-torque applications. However, spur configurations have higher backlash and are usually less efficient than planetary types of similar construction. For constant velocity and unidirectional applications where backlash is less of a concern, spur gearheads are ideal.