Centralized lubrication systems

select brand

Central lubrication system / air/oil - Spindl-Gard®

High-Speed Spindl-Gard® System incorporates a combination of air and oil lubrication scheme for spindle bearing application. It is equipped with an electric motor driven pump, which accommodates 3...

Central lubrication system / air/oil - Spindl-Gard®

High-Speed Spindl-Gard® System incorporates a combination of air and oil lubrication scheme for spindle bearing application. It is equipped with an electric motor driven pump, which accommodates 3...

Central lubrication system - Manzel MBL

With the help of standard modular components, you can provide the most reliable and co-effective cost-effective way...

Central lubrication system - Manzel MBL

With the help of standard modular components, you can provide the most reliable and co-effective cost-effective way to assemble customized oil systems with Manzel MBL Box Lubricator. The machine can successfully standardize lube system components and reduce the requirement lube maintenance and save on service costs. The lubricator can lubricate the cylinder walls, bearings and other moving parts of equipment. Can be configured to handle systems with 24 pumps.

Central lubrication system - Manzel 25

Manzel Model 25 Lubricator is an automatic metering for all kinds of machinery. It is used to give grease to chamber dividers, orientation and other moving parts of supplies,...

Central lubrication system - Manzel 25

Manzel Model 25 Lubricator is an automatic metering for all kinds of machinery. It is used to give grease to chamber dividers, orientation and other moving parts of supplies, for example, sugar factories, steam motors, presses and general apparatus.

The characteristics of the device include - universally useful oil that is programmed for exact metering of different apparatus, clear-Vue pumping unit shows measure of oil being pumped, independent, removable pumping unit. All units are compatible with removal of two pump screws and lift out. The advantageous hand wrenches for fast preparing of lines before start-up or for directly expanding supply of oil.

The characteristics of the device include - universally useful oil that is programmed for exact metering of different apparatus, clear-Vue pumping unit shows measure of oil being pumped, independent, removable pumping unit. All units are compatible with removal of two pump screws and lift out. The advantageous hand wrenches for fast preparing of lines before start-up or for directly expanding supply of oil.

Central lubrication system - Manzel HP-50

Manzel Model HP-50 High Pressure Lubricators are ideal for lubricating different functioning parts. The single plunger force feed configuration is profoundly proficient...

Central lubrication system - Manzel HP-50

Manzel Model HP-50 High Pressure Lubricators are ideal for lubricating different functioning parts. The single plunger force feed configuration is profoundly proficient for injecting lubricants and/or adaptable liquids into high pressure units. The vacuum sight feed on independent pumping systems show output of oils to each lubrication points.

The characteristics of the device include:

1. All functioning parts are completely confined and self-lubricated.

2. The pumping unit is effortlessly evacuated for self-services.

3. The feed rate varies from lowest to highest with basic manual adjustment.

The characteristics of the device include:

1. All functioning parts are completely confined and self-lubricated.

2. The pumping unit is effortlessly evacuated for self-services.

3. The feed rate varies from lowest to highest with basic manual adjustment.

Single-line lubrication system / central - SKF MonoFlex

The SKF Monoflex is a single-line lubrication system that uses various metering nipples (0.01 up to 2.5 cm³) for the separate lubricant requirement for each lubrication points. A piston metering...

Single-line lubrication system / central - SKF MonoFlex

The SKF Monoflex is a single-line lubrication system that uses various metering nipples (0.01 up to 2.5 cm³) for the separate lubricant requirement for each lubrication points. A piston metering...

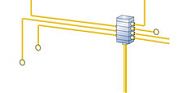

Dual line lubrication system / central - SKF DuoFlex

SKF DuoFlex systems are suitable for medium to large-sized machines with a number of lubrication points, long lines, and demanding operating environments. Its double-line lube systems delivers more than 1000...

Dual line lubrication system / central - SKF DuoFlex

SKF DuoFlex systems are suitable for medium to large-sized machines with a number of lubrication points, long lines, and demanding operating environments. Its double-line lube systems delivers more than 1000 lubrication points from just one pump source with pressures until 400 bar, making it very reliable. It is easy to configure and install, with its parallel metering valves.

SKF DuoFlex systems utilize 2 main lines that are alternately lubricated. It is ideal when handling tough greases, and across distances of 100 m or more. The machine is very versatile, it adapts to the different quantities and needs of certain lubrication points. These systems are commonly used in heavy-duty industries, metal working plants, pulp and paper, mining, mineral processing, and many other application options.

SKF DuoFlex systems utilize 2 main lines that are alternately lubricated. It is ideal when handling tough greases, and across distances of 100 m or more. The machine is very versatile, it adapts to the different quantities and needs of certain lubrication points. These systems are commonly used in heavy-duty industries, metal working plants, pulp and paper, mining, mineral processing, and many other application options.

Multi-line lubrication system / central - SKF MultiFlex

This multiple line power lubrication system is made with different NLGI grease grades 000 to 3 representing oil, semi-fluid grease and hard grease....

Multi-line lubrication system / central - SKF MultiFlex

This multiple line power lubrication system is made with different NLGI grease grades 000 to 3 representing oil, semi-fluid grease and hard grease. The SKF Multi Flex brand systems are planned both for automatic and circulating oil systems in industries like machine tool, oil and gas and heavy machinery. Every lubrication point has an independent pumping part. The diverse outlets supply the lubricants directly to lube point.

The system is easy to follow, reliable and precise. The SKF Multi Flex comes with outlets ranging one to 32 and can withstand pressure up to 4,000bar.

The system is easy to follow, reliable and precise. The SKF Multi Flex comes with outlets ranging one to 32 and can withstand pressure up to 4,000bar.

Central greasing system - SKF ProFlex

The SKF ProFlex is a lubrication system which is integrated with a feed pump, a device that controls the flow and distributes a specific volume of lubricant into each outlet. It is suited...

Central greasing system - SKF ProFlex

The SKF ProFlex is a lubrication system which is integrated with a feed pump, a device that controls the flow and distributes a specific volume of lubricant into each outlet. It is suited...

Central lubrication system / closed-circuit / oil - SKF CircOil

As opposed to aggregate oil loss frameworks, after the oil passes through the point that demands proper lubrication, it is sustained once again through the return line into the oil repository for reuse function....

Central lubrication system / closed-circuit / oil - SKF CircOil

As opposed to aggregate oil loss frameworks, after the oil passes through the point that demands proper lubrication, it is sustained once again through the return line into the oil repository for reuse function. Aside from greasing up, flowing oil grease performs an extent of different capacities. It balances out the oil focus to the best possible temperature, evacuates and channels out wear particles from friction points, counteracts erosion harm, and uproots water buildup. Coursing oil frameworks could be delegated after the ointment conveyed by a pump is part up by water-driven resistors including hole tubes, movable metering valve merchants, throttles. The real sustain rates could be controlled outwardly or electronically.

This system integrates an efficient cooling system, thus improving the lubricating performance.

This system integrates an efficient cooling system, thus improving the lubricating performance.