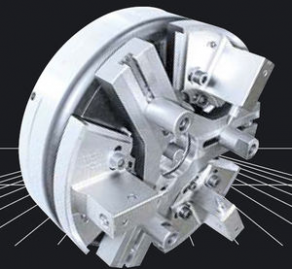

Lathe chuck - ø 6 - 300 mm | SM

The SM diaphragm clamping system is used for special productions, such as high-precision gear wheels. This process involves keeping the concentricity deviations between the reference circle and the seating bore as small as possible.

The SM diaphragm clamping system is used for special productions, such as high-precision gear wheels. This process involves keeping the concentricity deviations between the reference circle and the seating bore as small as possible.The clamping element is a washer-shaped diaphragm, preferably with three clamping jaws. If the application involves thin-walled workpieces, the diaphragm can also be designed with four or six clamping jaws. These are either cut out of the diaphragm or screwed onto it.

The SM clamping system facilitates clamping the gear wheel in the reference circle in order to machine the seating bore. Applying an axial force to the diaphragm causes it to deflect. This causes the clamping jaws to move axially and simultaneously open radially. The gear wheel is released.

Be reducing or eliminating the axial force, the diaphragm returns to its original position due to its own spring-like property. The gear wheel is clamped both radially and axially.