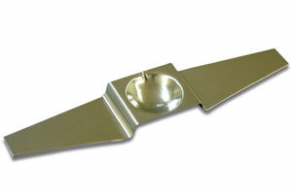

Evaporation boat

Plansee's thermal vacuum evaporation is a coating procedure used as part of Physical Vapor Deposition process. The component that will make the subsequent layer is heated inside the vacuum chamber until it evaporates.

Plansee's thermal vacuum evaporation is a coating procedure used as part of Physical Vapor Deposition process. The component that will make the subsequent layer is heated inside the vacuum chamber until it evaporates. The vapor formed by the material condenses on the substrate and makes the needed layer. This process is made in a high vacuum because numerous cutting materials react with nitrogen, water and oxygen.

The high temperatures that are required are created using resistance heaters or induction heaters, electron beams or arcs. The evaporation boats are constructed from refractory metals like molybdenum, tungsten or tantalum to resist high temperatures and chemical aggression.