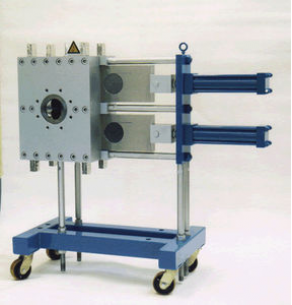

Continuous screen changer / hydraulic / double slide plate - max. 11 000 kg/h | CFSC series

The Contiflow filters polymers without interrupting the melt and expels air from the incoming breaker plate as it enters the melt flow. The two slide plates have a slow movement, allowing the incoming breaker plate to pre-fill with polymer.

The Contiflow filters polymers without interrupting the melt and expels air from the incoming breaker plate as it enters the melt flow. The two slide plates have a slow movement, allowing the incoming breaker plate to pre-fill with polymer.Has a patented, fully automatic sealing system, and is designed specifically for extrusion processes, which do not allow air entrapment in the melt flow during a screen change.

Ideal for blown and cast film, sheet, strands and pipes production and any other critical processes, non-compatible with air entrapment.

Available in two- and four-breaker-plate models to suit any process requirement. Can be electrically, oil or steam heated. Suitable for working temperatures up to 280˚ C and melt pressures up to 350 BAR.

Available sizes:

Models: Typical Output:

CFSC 70 350 kg/h

CFSC 100 800 kg/h

CFSC 120

1,300 kg/h

CFSC 150 2,000 kg/h

CFSC 210

2,500 kg/h

CFSC 250

5,000 kg/h

CFSC 300 11,000 kg/h