Shrink film extrusion line / blown film - 300 kg/h | S series

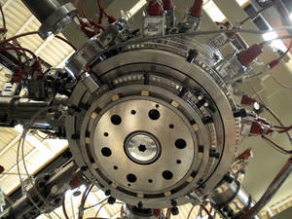

The orientation line works using a so called double bubble process. The polymer is extruded through the circular die and is immediately water quenched so as to form a thick primary tube that is re-heated to a suitable temperature and then blown so as to form the main bubble of thin film. The non-contactsimultaneous orientation which is achieved thanks to the air inflation during the star tup phase. The air allows the transversal orientation as the machine direction orientation is taken simultaneously due to the speed difference between the stretching nip roll and the tower nip roll. The bubble is air cooled and is then flattened. The third bubble is annealed via ovens through the ceramic infra-red heater. The final product can be wound in a tube of fat film.

The orientation line works using a so called double bubble process. The polymer is extruded through the circular die and is immediately water quenched so as to form a thick primary tube that is re-heated to a suitable temperature and then blown so as to form the main bubble of thin film. The non-contactsimultaneous orientation which is achieved thanks to the air inflation during the star tup phase. The air allows the transversal orientation as the machine direction orientation is taken simultaneously due to the speed difference between the stretching nip roll and the tower nip roll. The bubble is air cooled and is then flattened. The third bubble is annealed via ovens through the ceramic infra-red heater. The final product can be wound in a tube of fat film.

Any questions?

Please ask our sales team!

The orientation line works using a so called double bubble process. The polymer is extruded through the circular die and is immediately water quenched so as to form a thick primary tube that is re-heated to a suitable temperature and then blown so as to form the main bubble of thin film. The non-contactsimultaneous orientation which is achieved thanks to the air inflation during the star tup phase. The air allows the transversal orientation as the machine direction orientation is taken simultaneously due to the speed difference between the stretching nip roll and the tower nip roll. The bubble is air cooled and is then flattened. The third bubble is annealed via ovens through the ceramic infra-red heater. The final product can be wound in a tube of fat film.

The orientation line works using a so called double bubble process. The polymer is extruded through the circular die and is immediately water quenched so as to form a thick primary tube that is re-heated to a suitable temperature and then blown so as to form the main bubble of thin film. The non-contactsimultaneous orientation which is achieved thanks to the air inflation during the star tup phase. The air allows the transversal orientation as the machine direction orientation is taken simultaneously due to the speed difference between the stretching nip roll and the tower nip roll. The bubble is air cooled and is then flattened. The third bubble is annealed via ovens through the ceramic infra-red heater. The final product can be wound in a tube of fat film.