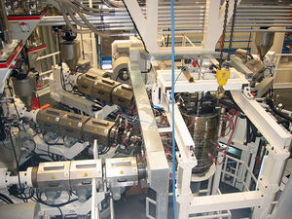

Blown film extrusion line - max. 400 kg/h

The double bubble extrusion line directs the line works in industries. It ejects the polymers through a circular die and instantly water-quenches them to form a thick primary tube. The Primary tube is then re-heated up to a specific temperature and blown for the formation of main bubble of thin film.

The double bubble extrusion line directs the line works in industries. It ejects the polymers through a circular die and instantly water-quenches them to form a thick primary tube. The Primary tube is then re-heated up to a specific temperature and blown for the formation of main bubble of thin film.It manages non-contact simultaneous orientation due to the air inflated at the time of the start up phase. This air permits the transversal orientation. The machine direction orientation is done at the same time due to variation of speed between the stretching nip roll and the tower nip roll. The bubble is cooled by air and then flattened. Thereafter, the edges are trimmed and two webs rolled up in two reels are acquired. It is plausible to get heat set film like BOPP, BOPA, BOPET and custom products by annealing the product acquired on the biorientation machine.