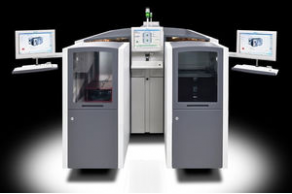

SMT pick-and-place machine / automatic - 9 000 - 20 000 cph | SIPLACE CA series

As the world's first placement platform that incorporates bare-die from the wafer and classic SMT placement in a single machine and production process, the SIPLACE CA provides many benefits. This adds up to less special processes and higher productivity for modern products that involves flip-chips and die-attach for electrical manufacturers. With each of its SIPLACE SpeedStar heads, it places up to 9000 flip-chips or attaches up to 6500 dies in just an hour. Each material is supplied through the SIPLACE wafer system from wafers from 4 to 12 inches in diameter. The two units along with the Linear Dipping Unit completes the equipment of SIPLACE CA that results to its flexibility and accuracy in bare-die placement operations. Meanwhile, the gantries and heads of the SIPLACE that remain unused can be supplied through the component carts and X feeders.

As the world's first placement platform that incorporates bare-die from the wafer and classic SMT placement in a single machine and production process, the SIPLACE CA provides many benefits. This adds up to less special processes and higher productivity for modern products that involves flip-chips and die-attach for electrical manufacturers. With each of its SIPLACE SpeedStar heads, it places up to 9000 flip-chips or attaches up to 6500 dies in just an hour. Each material is supplied through the SIPLACE wafer system from wafers from 4 to 12 inches in diameter. The two units along with the Linear Dipping Unit completes the equipment of SIPLACE CA that results to its flexibility and accuracy in bare-die placement operations. Meanwhile, the gantries and heads of the SIPLACE that remain unused can be supplied through the component carts and X feeders.

Any questions?

Please ask our sales team!

As the world's first placement platform that incorporates bare-die from the wafer and classic SMT placement in a single machine and production process, the SIPLACE CA provides many benefits. This adds up to less special processes and higher productivity for modern products that involves flip-chips and die-attach for electrical manufacturers. With each of its SIPLACE SpeedStar heads, it places up to 9000 flip-chips or attaches up to 6500 dies in just an hour. Each material is supplied through the SIPLACE wafer system from wafers from 4 to 12 inches in diameter. The two units along with the Linear Dipping Unit completes the equipment of SIPLACE CA that results to its flexibility and accuracy in bare-die placement operations. Meanwhile, the gantries and heads of the SIPLACE that remain unused can be supplied through the component carts and X feeders.

As the world's first placement platform that incorporates bare-die from the wafer and classic SMT placement in a single machine and production process, the SIPLACE CA provides many benefits. This adds up to less special processes and higher productivity for modern products that involves flip-chips and die-attach for electrical manufacturers. With each of its SIPLACE SpeedStar heads, it places up to 9000 flip-chips or attaches up to 6500 dies in just an hour. Each material is supplied through the SIPLACE wafer system from wafers from 4 to 12 inches in diameter. The two units along with the Linear Dipping Unit completes the equipment of SIPLACE CA that results to its flexibility and accuracy in bare-die placement operations. Meanwhile, the gantries and heads of the SIPLACE that remain unused can be supplied through the component carts and X feeders.