Tapping units

select brand

Rigid coupling / stainless / robotic / pallet - 4 000 Nm, 200 kN | VERO-S NSR maxi 220

Stronger than ever

The new robot coupling VERO-S NSR maxi 220 makes handling of heavy pallets (1,000 kg with pallet size 800 x 800 mm) easier and safer. Its high pull-in force of 75 kN creates an unusually rigid system, with an outstanding holding force which permits high torques.

Monitoring...

The new robot coupling VERO-S NSR maxi 220 makes handling of heavy pallets (1,000 kg with pallet size 800 x 800 mm) easier and safer. Its high pull-in force of 75 kN creates an unusually rigid system, with an outstanding holding force which permits high torques.

Monitoring...

Rigid coupling / stainless / robotic / pallet - 4 000 Nm, 200 kN | VERO-S NSR maxi 220

Stronger than ever

The new robot coupling VERO-S NSR maxi 220 makes handling of heavy pallets (1,000 kg with pallet size 800 x 800 mm) easier and safer. Its high pull-in force of 75 kN creates an unusually rigid system, with an outstanding holding force which permits high torques.

Monitoring for maximum process reliability

The clamping slide position of the module is monitored by the inductive stroke measuring system. Combined with the pallet presence monitoring, this help guarantee maximum process reliability. An integrated cleaning function for all contact surfaces minimizes the wear during the pallet change.

Product features

Maximum pull-in forces: up to 75 N

Maximum transferable torque: 4,000 Nm

Module completely sealed

Form-fit locking with self-locking

All parts in stainless, hardened steel

Air purge with cleaning function on all functional surfaces

Two options for securing it against twisting: via cylindrical pins or via the external slope (patented)

All monitoring integrated as standard: clamping position (opened / closed) and pallet presence

No lubriated required

Extremely compact dimensions (L x W x H: 220 x 180 x 108 mm)

The new robot coupling VERO-S NSR maxi 220 makes handling of heavy pallets (1,000 kg with pallet size 800 x 800 mm) easier and safer. Its high pull-in force of 75 kN creates an unusually rigid system, with an outstanding holding force which permits high torques.

Monitoring for maximum process reliability

The clamping slide position of the module is monitored by the inductive stroke measuring system. Combined with the pallet presence monitoring, this help guarantee maximum process reliability. An integrated cleaning function for all contact surfaces minimizes the wear during the pallet change.

Product features

Maximum pull-in forces: up to 75 N

Maximum transferable torque: 4,000 Nm

Module completely sealed

Form-fit locking with self-locking

All parts in stainless, hardened steel

Air purge with cleaning function on all functional surfaces

Two options for securing it against twisting: via cylindrical pins or via the external slope (patented)

All monitoring integrated as standard: clamping position (opened / closed) and pallet presence

No lubriated required

Extremely compact dimensions (L x W x H: 220 x 180 x 108 mm)

In-die tapping unit

The modularity of the PRONIC tapping solution provides you with the choice of a mechanical or servo driven system.

However, each of these technologies has its own application cases.

The...

However, each of these technologies has its own application cases.

The...

In-die tapping unit

The modularity of the PRONIC tapping solution provides you with the choice of a mechanical or servo driven system.

However, each of these technologies has its own application cases.

The Mechanical tapping unit is the preferred choice for most progressive dies, and it is sometimes also a good choice for tranfer presses.

The use of the servo driven tapping unit makes sense for :

dies running with very large press stroke, over 500mm (20)

dies with very short press stroke, less than 50 mm (2)

dies with short Shut Height

tapping units running in transfer presses

Fineblanking applications

Multi slide presses

Stand alone / off line tapping

Progressive dies running with several different press strokes.

However, each of these technologies has its own application cases.

The Mechanical tapping unit is the preferred choice for most progressive dies, and it is sometimes also a good choice for tranfer presses.

The use of the servo driven tapping unit makes sense for :

dies running with very large press stroke, over 500mm (20)

dies with very short press stroke, less than 50 mm (2)

dies with short Shut Height

tapping units running in transfer presses

Fineblanking applications

Multi slide presses

Stand alone / off line tapping

Progressive dies running with several different press strokes.

Mechanical tapping unit

Our simple and highly reliable mechanical tapping solutions answer more than 80% of all tapping applications.

This...

This...

Mechanical tapping unit

Our simple and highly reliable mechanical tapping solutions answer more than 80% of all tapping applications.

This unique system utilizes a threaded drive shaft and threaded nut thus converting the linear motion of the press ram into a rotation. The rotary movement of the nut is transferred with a train of gears to a lead screw assembly that pilots the tap. These tapping units can be installed on a pressure pad, solid on the lower shoe or on the stripper.

This unique system utilizes a threaded drive shaft and threaded nut thus converting the linear motion of the press ram into a rotation. The rotary movement of the nut is transferred with a train of gears to a lead screw assembly that pilots the tap. These tapping units can be installed on a pressure pad, solid on the lower shoe or on the stripper.

Tapping unit - TKx series

These in-die tapping units are designed with a removable head and may be used for single or multi-tap applications. The tapping head is driven either by mechanical...

Tapping unit - TKx series

These in-die tapping units are designed with a removable head and may be used for single or multi-tap applications. The tapping head is driven either by mechanical or by servo-driven mtorization. the two-part design simplifies operations and enables quick tap change.

These units have been studied to integrate the commonly installed functions in the die directly and compactly in the tapping head.

According to the proposed version, the turnkey "TK" solution integrates the following functions:

Strip guiding,

Vertical strip follow (strip lift)

Quick approach of the tapping head and strip piloting.

These units have been studied to integrate the commonly installed functions in the die directly and compactly in the tapping head.

According to the proposed version, the turnkey "TK" solution integrates the following functions:

Strip guiding,

Vertical strip follow (strip lift)

Quick approach of the tapping head and strip piloting.

In-die tapping unit - M1B - M1D

The M1B & M1D are 100% mechanical, with an adjustable gearbox. They are the simplest in die tapping units to use and/or re-use within different...

In-die tapping unit - M1B - M1D

The M1B & M1D are 100% mechanical, with an adjustable gearbox. They are the simplest in die tapping units to use and/or re-use within different...

Tapping unit - BxB, B+xB

These models are commonly used to tap electrical components such as contactors, etc they are the best solution for applications...

Tapping unit - BxB, B+xB

These models are commonly used to tap electrical components such as contactors, etc they are the best solution for applications with small distance centers and small tap sizes within a high speed press.

Usually installed within small dies, they are made to handle the highest volumes of production. The technology is 100% mechanical; the planetary gears are a PRONIC patented product.

Based upon the shape of your part, PRONIC will create the best module for your application.

Usually installed within small dies, they are made to handle the highest volumes of production. The technology is 100% mechanical; the planetary gears are a PRONIC patented product.

Based upon the shape of your part, PRONIC will create the best module for your application.

Tappers drilling head / cutting

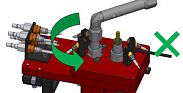

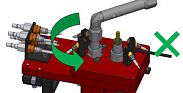

Six Station Drilling and Tapping Turret

The turret allows drilling and tapping with six tools and rapid tool changing.

Equipped...

The turret allows drilling and tapping with six tools and rapid tool changing.

Equipped...

Tappers drilling head / cutting

Six Station Drilling and Tapping Turret

The turret allows drilling and tapping with six tools and rapid tool changing.

Equipped...

The turret allows drilling and tapping with six tools and rapid tool changing.

Equipped...